How Modified Bumper Molding Improves Durability and Reduces Repair Costs

Modified bumper molding is a critical component in the automotive industry, offering enhanced design and protection for vehicle bumpers. This molding process involves modifying traditional bumpers with materials and techniques that provide improved durability, aesthetics, and functionality. While the initial cost of modified bumper molding may be higher than standard bumpers, its cost-effectiveness becomes evident through long-term benefits such as reduced maintenance, better performance, and overall value.

Improved Durability and Longevity

One of the main advantages of modified bumper molding is its durability. These bumpers are often made from stronger materials or treated with advanced processes to resist impacts, weathering, and UV damage. As a result, they are less likely to require frequent repairs or replacements compared to standard bumpers. The ability to withstand the rigors of daily driving means lower long-term maintenance costs, making modified bumper molding a more cost-effective choice for vehicle manufacturers and owners.

Enhanced Aesthetic Appeal

Modified bumper molding also contributes to the aesthetic appeal of a vehicle, offering more design flexibility. The ability to incorporate different materials, colors, and finishes allows manufacturers to create bumpers that better match the vehicle's overall style. While this customization may have a slightly higher upfront cost, the added value in terms of visual appeal and brand differentiation can translate to increased marketability and customer satisfaction, making it a worthwhile investment for automakers.

Reduced Repair Costs

Modified bumper moldings can reduce the frequency and expense of repairs over time. Their enhanced impact resistance means they are less likely to suffer visible damage from minor collisions or accidents. This results in fewer instances of repairs or part replacements, reducing overall ownership costs. Additionally, some advanced modified bumpers feature repairable surfaces, which further decrease the cost of maintenance.

https://www.bumpermould.net/product/auto-parts-mould/plastic-injection-auto-mould-for-audi-a6-side-beam-a3-wheel-brow.html

https://www.bumpermould.net/product/auto-parts-mould/plastic-injection-auto-mould-for-audi-a6-side-beam-a3-wheel-brow.html

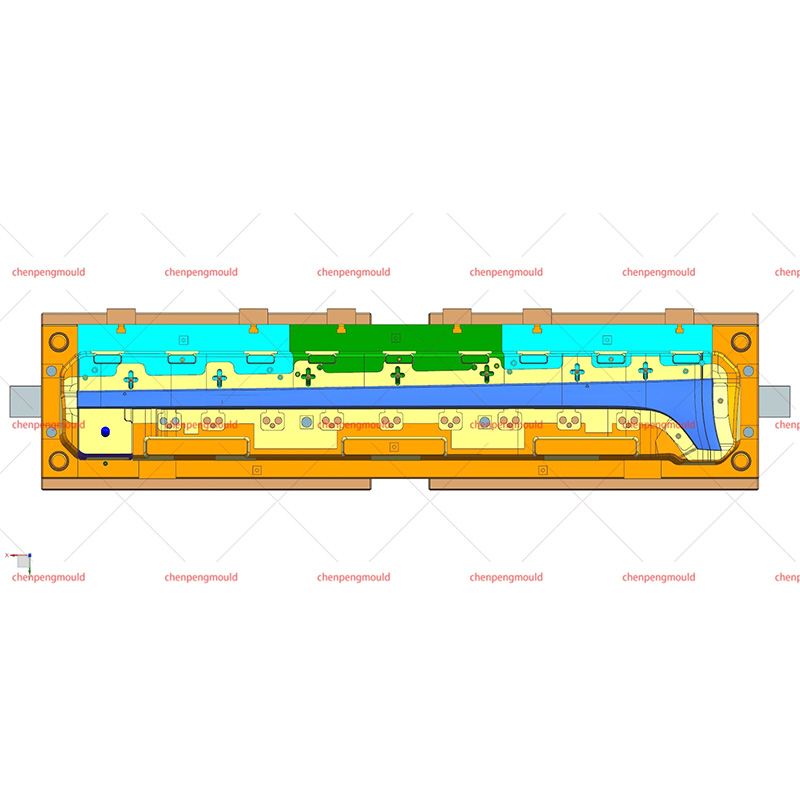

Steel For Cavity &. Core P20

Mould Base C40

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

Mould Estimated Size 2200 x 950 x 1000mm

Mould Weight 12500KG

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Social