How Brass Motorized Valves Enhance Efficiency and Reduce Operational Costs

Brass motorized valves are widely used in fluid control systems across various industries due to their durability, reliability, and precision. These valves are designed to automate the control of fluid flow, offering significant advantages in terms of operational efficiency and reduced labor costs. While the initial investment may be higher than manual valves, the long-term cost-effectiveness of brass motorized valves becomes evident in several key areas.

Reduced Labor and Maintenance Costs

One of the primary benefits of brass motorized valves is the reduction in labor costs. With automated control, there is less need for manual intervention to regulate fluid flow, leading to increased operational efficiency. In applications like HVAC systems, water treatment plants, and industrial processes, brass motorized valves can operate continuously with minimal human oversight. This reduces the need for frequent monitoring, manual adjustments, and maintenance, resulting in lower labor costs over time. Additionally, brass is a highly durable material that resists corrosion and wear, minimizing maintenance needs and extending the lifespan of the valves.

Increased System Efficiency

Brass motorized valves also contribute to enhanced system efficiency. These valves can be precisely controlled to regulate fluid flow based on demand, ensuring optimal operation of pumps, heaters, and other components. By maintaining the ideal flow rate, motorized valves can help prevent system overuse or underuse, which can lead to energy waste. This precise control of fluid dynamics helps improve overall energy efficiency, resulting in lower utility bills and a more cost-effective operation in the long run.

Long-Term Durability and Reliability

Brass motorized valves are known for their robustness and longevity. The material's resistance to corrosion and wear ensures that these valves can withstand demanding environments, such as those in industrial and water management systems. Their reliability reduces the frequency of replacements and repairs, which contributes to long-term savings.

https://www.kyodavalve.com/product/brass-manifold/stainless-steel-manifold-kit.html

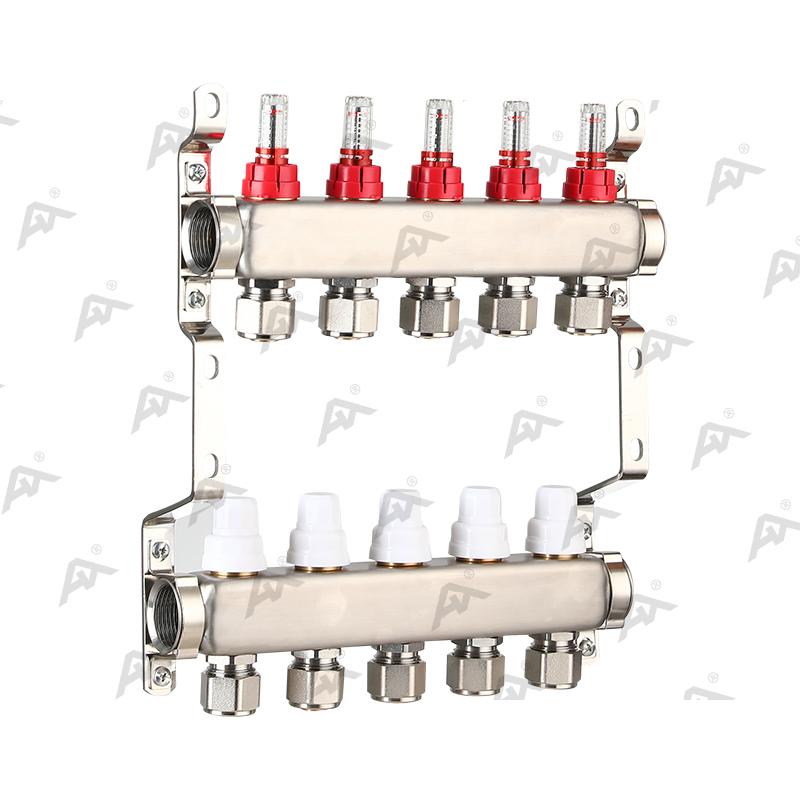

The Stainless Steel Manifold Kit is designed with versatility in mind. Compatible with a wide range of floor heating systems, it seamlessly integrates into both residential and commercial applications. Whether you are renovating your home or designing a new commercial space, this manifold kit offers adaptability to various heating configurations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Social