How Punch Press Machines Reduce Costs Through Efficiency and Material Savings

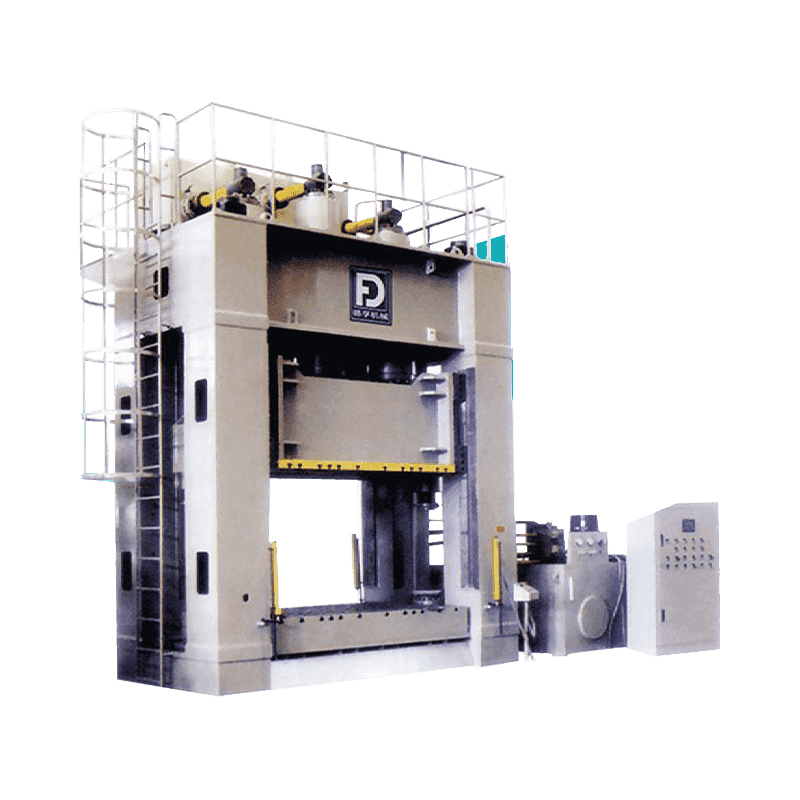

Punch press machines factory are essential tools in metalworking, widely used for punching, stamping, and shaping metal sheets into various shapes and sizes. These machines provide high efficiency, speed, and precision, making them indispensable in industries such as automotive, electronics, and manufacturing. While the initial investment in punch press machines may seem significant, their long-term cost-effectiveness becomes evident in terms of productivity, maintenance, and material savings.

Increased Production Efficiency

One of the key factors contributing to the cost-effectiveness of punch press machines is their ability to increase production efficiency. These machines can perform high-volume tasks quickly, reducing the amount of time required to manufacture parts. Automated punch presses, in particular, are designed for continuous operation with minimal supervision, ensuring that production lines remain active, reducing downtime, and allowing for more parts to be produced within a shorter period. This efficiency translates to reduced labor costs and faster production cycles, ultimately lowering the cost per part.

Reduced Material Waste

Punch press machines are designed to maximize the use of materials, ensuring minimal waste during the manufacturing process. By using advanced tools and technology, punch presses can optimize material placement and cutting, reducing scrap rates. This material efficiency is particularly important in industries where raw materials are expensive, such as in the aerospace or automotive sectors. The reduced material waste helps keep overall production costs lower, increasing the return on investment for manufacturers.

Low Maintenance and Longevity

Another reason why punch press machines are cost-effective is their relatively low maintenance requirements. With proper care, these machines can have a long operational life, further reducing the need for frequent repairs or replacements. Their durability, coupled with easy-to-replace parts, ensures that punch presses remain productive over time without incurring significant maintenance costs.

https://www.zjdfjx.cn/product/hydraulic-press-machinery/gantrylever-type-single-action-sheet-stretching-machine.html

https://www.zjdfjx.cn/product/hydraulic-press-machinery/gantrylever-type-single-action-sheet-stretching-machine.html

The Gantry Pull-Rod Single-Action Sheet Stretcher is a highly efficient and versatile machine that has revolutionized the manufacturing industry. This machine is designed to stretch sheets of metal or other materials into various shapes and sizes, making it ideal for a wide range of applications.

The Gantry Pull-Rod Single-Action Sheet Stretcher uses advanced technology to ensure precise control over the stretching process, resulting in consistent and accurate results every time. This means that manufacturers can produce large quantities of products quickly and easily, without sacrificing quality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Social