How to Select the Ideal Mould for Plastic Cups

When manufacturing plastic cups, selecting the right mould is crucial for producing high-quality, durable, and cost-effective products. The mould not only determines the shape and size of the cups but also affects production efficiency and overall product performance. Below are some key factors to consider when choosing the right mould for plastic cups.

Material Compatibility

The first consideration when selecting a mould for plastic cups is material compatibility. Plastic cups are commonly made from materials like polypropylene, polystyrene, or PET. Ensure that the mould is designed to handle the specific material you plan to use, as different plastics have varying melting points, flow characteristics, and cooling rates. A mould that is not compatible with the chosen plastic can lead to defects, inconsistencies, or poor-quality products.

Mould Design and Precision

Mould design plays a significant role in determining the quality of the final product. The mould should be designed to produce the desired shape with high precision and uniformity. Look for moulds that have tight tolerances to ensure that each plastic cup produced is consistent in size and shape. The mould's design should also include features like proper venting and cooling systems to prevent defects such as warping or air pockets.

Production Volume and Efficiency

The required production volume is another important factor in mould selection. For large-scale production, consider multi-cavity moulds that can produce several cups simultaneously. This can increase production speed and efficiency. On the other hand, for smaller production runs or specialized cups, single-cavity moulds may be more cost-effective and sufficient for meeting demand. Additionally, evaluate the cycle time and ease of maintenance of the mould to ensure long-term efficiency.

https://www.food-container-mold.com/product/disposable-plastic-square-food-container-moulds/square-product-mold.html

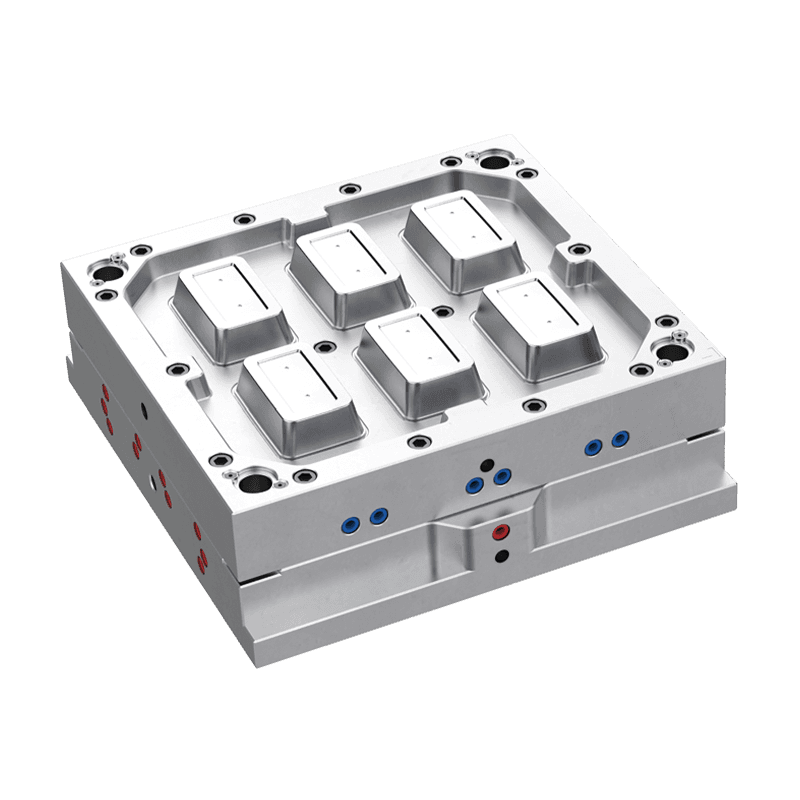

The Disposable Plastic Square Food Container Mold is a high-precision plastic injection mold designed to produce plastic boxes and lids with excellent sealing performance. Engineered for efficiency, this mold ensures a swift molding cycle of just 6 seconds or within 6-8 seconds. Customizable to meet specific requirements, the Disposable Plastic Square Food Container Mold is made from durable PP (polypropylene) material, ensuring longevity and reliability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Social