Plastic Bucket Cap Moulds: The Art of Seamless Integration

One of the primary functions of plastic injection bucket cap moulds is to ensure precision and consistency in the production of caps. The moulds are engineered to exact specifications, allowing for the mass production of caps that are identical in shape, size, and fit. This uniformity is crucial for maintaining product quality and ensuring that each bucket cap performs its intended function effectively.

Another function of these moulds is to optimize material usage. By designing moulds that waste, manufacturers can reduce the amount of plastic needed to produce each cap, cost savings and a reduced environmental impact. The moulds are crafted in such a way that they use the material efficiently, with minimal flash or excess material that would otherwise be discarded.

The durability and strength of bucket caps are directly related to the quality of the moulds used in their production. High-quality moulds produce caps that can withstand the rigors of daily use, including exposure to various weather conditions and the physical stress of being handled repeatedly. The moulds are made from robust materials that can withstand the high pressures and temperatures involved in the injection moulding process, ensuring that the caps they produce are equally resilient.

Plastic injection bucket cap moulds offer a high degree of customization, allowing manufacturers to create caps that cater to specific needs. Whether it's a cap for a food-grade bucket that requires airtight seals or a cap for a paint bucket that needs a built-in pour spout, moulds can be designed to accommodate these features. This versatility is a significant advantage for manufacturers looking to diversify their product offerings and meet the unique requirements of different markets.

https://www.ysmou.com/product/cap-mould/plastic-injection-bucket-cap-mould-with-antitheft-ring.html

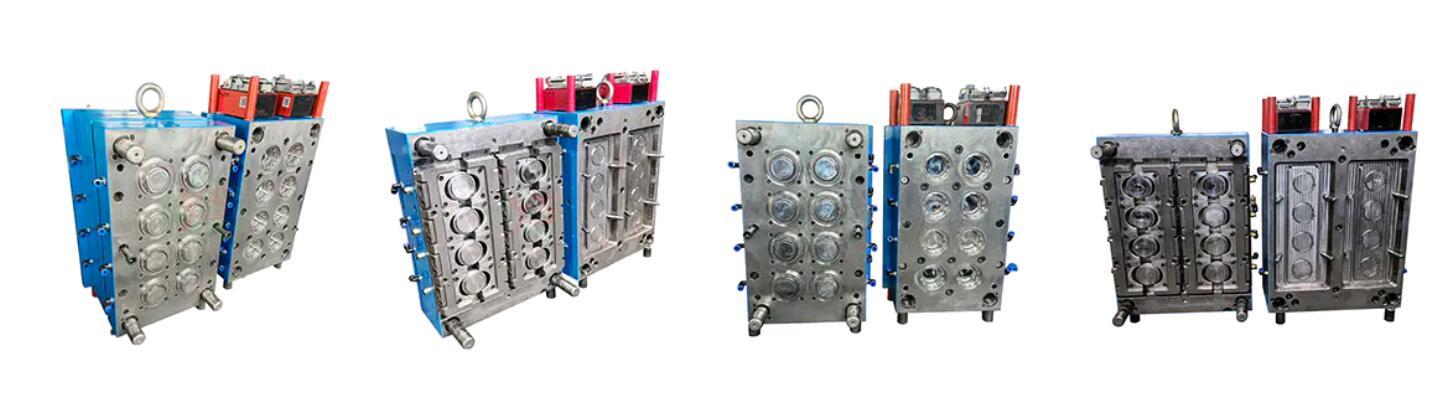

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic motor, requiring manual installation without much effort.

During the processing, we strictly control each step and test to ensure product quality and delivery time. After each sample is confirmed by the customer for quality, it is arranged for shipment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Social